Guide to Modern Laser Welding: Techniques, Tools, and Applications

Introduction to Advanced Laser Welding Applications

Laser welding technology is a transformative force in modern manufacturing, offering precision, speed, and efficiency that traditional methods often struggle to match. This advanced technique is utilized in a variety of industries, from automotive to medical manufacturing, due to its ability to create strong, clean welds with minimal distortion. The precision of laser welding not only improves joint strength but also reduces clean-up time, making it a preferred choice for intricate and high-stakes applications.

One of the key advantages of laser welding is its versatility. It can join a wide range of materials, including metals and plastics, which makes it suitable for diverse applications. In the automotive industry, laser welders are used to create lightweight, durable components, while in the medical field, they are essential for producing precise surgical tools and implants. This adaptability is one of the reasons laser welding is gaining traction as a go-to solution for complex manufacturing challenges.

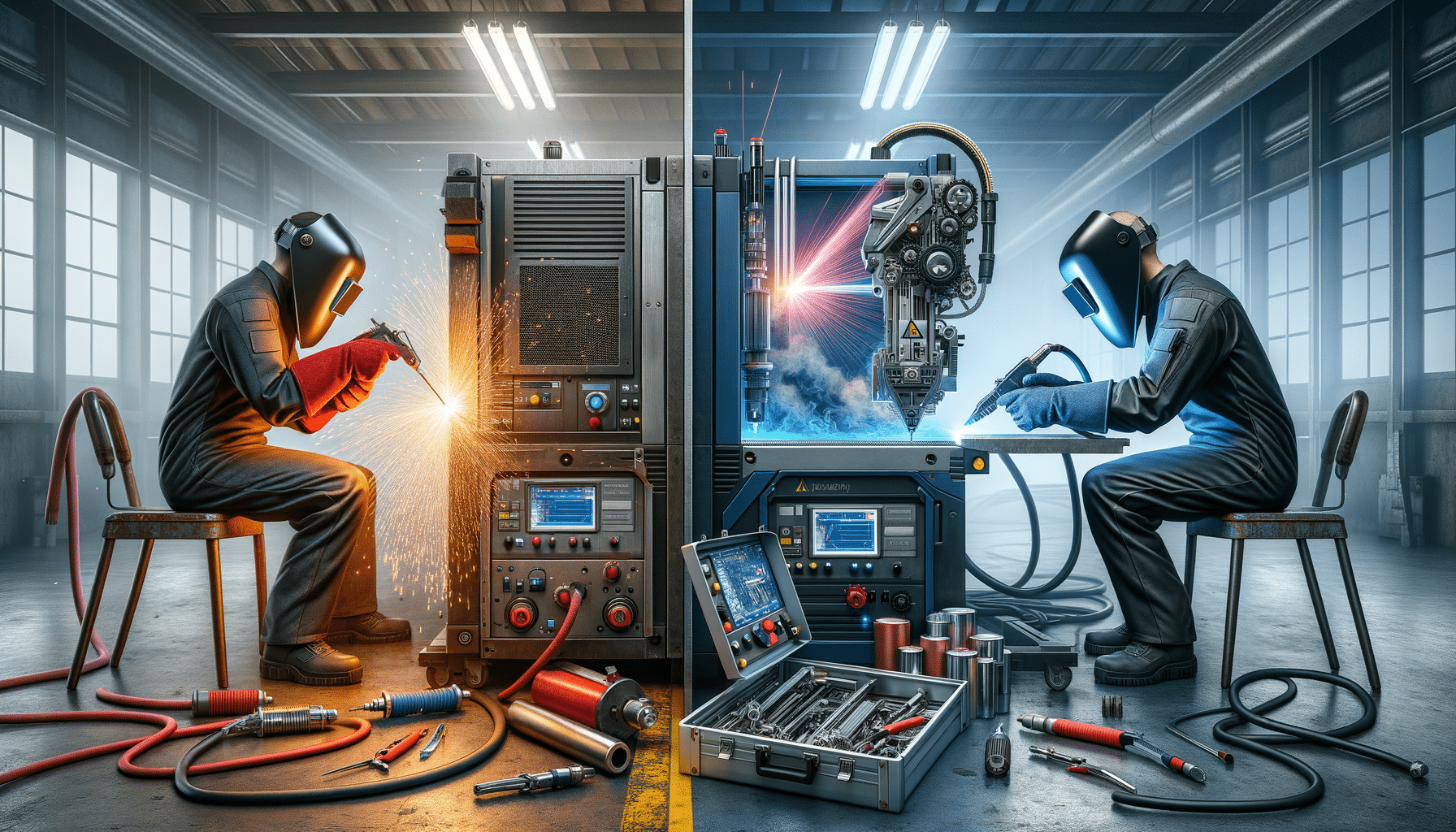

Exploring the Differences Between TIG, MIG, and Laser Welding

Understanding the distinctions between TIG, MIG, and laser welding is essential for selecting the appropriate method for a given task. Each technique has its own strengths and is suited to different applications. TIG (Tungsten Inert Gas) welding is known for its precision and is often used for thin materials and detailed work. It requires a high level of skill and is slower compared to other methods.

MIG (Metal Inert Gas) welding, on the other hand, is faster and easier to learn. It is commonly used for thicker materials and is favored in industries that require high production rates. However, it may not provide the same level of precision and clean finish as TIG or laser welding.

Laser welding stands out by offering a unique combination of speed, precision, and minimal heat input. This results in less distortion and a cleaner finish, making it ideal for applications where aesthetics and structural integrity are critical. Exploring the differences between TIG, MIG, and laser welding helps manufacturers choose the right tool for their specific needs, optimizing both efficiency and quality.

Tools and Safety Gear Used in Precision Laser Weld Operations

Precision laser welding requires specialized tools and safety gear to ensure both effective operation and safety. Essential tools include the laser welding machine itself, which can vary in size and power depending on the application. Additional equipment such as positioning systems and cooling units may be necessary for specific tasks.

Safety is paramount in laser welding operations. Operators must wear appropriate safety gear, including laser safety glasses, which protect the eyes from intense laser light. Protective clothing is also important to shield the skin from potential exposure. Furthermore, a well-ventilated workspace is crucial to prevent the accumulation of fumes and particulates generated during the welding process.

Understanding the tools and safety gear used in precision laser weld operations is vital for maintaining a safe and efficient working environment. Proper training and adherence to safety protocols are essential to prevent accidents and ensure high-quality welds.

Use Cases for Laser Welders in Automotive and Medical Manufacturing

Laser welders have become indispensable in both automotive and medical manufacturing, where precision and reliability are critical. In the automotive industry, laser welding is used to create lightweight, durable components that contribute to fuel efficiency and vehicle performance. It is also employed in the production of safety-critical parts, such as airbags and seatbelt components, where the integrity of the weld is paramount.

In the medical field, laser welders are used to manufacture surgical instruments, implants, and other medical devices. The precision of laser welding ensures that these products meet stringent quality standards and can withstand the rigors of medical use. The ability to create strong, clean welds with minimal heat input is particularly important in this industry, where even minor defects can have serious consequences.

Understanding the use cases for laser welders in automotive and medical manufacturing highlights the versatility and importance of this technology in producing high-quality products across various sectors.

What to Consider When Setting Up a Small-Scale Laser Welding Station

Setting up a small-scale laser welding station requires careful planning and consideration of several factors to ensure efficiency and safety. The first step is selecting the appropriate laser welding machine, which should be based on the types of materials and thicknesses you intend to work with. It’s also important to consider the power requirements and space constraints of your workshop.

Next, ensure that you have the necessary tools and safety gear, such as laser safety glasses and protective clothing. A well-ventilated workspace is crucial to prevent the buildup of harmful fumes. Additionally, consider investing in a fume extraction system to maintain air quality and protect the health of operators.

Finally, training is a key component of setting up a successful laser welding station. Operators should be well-versed in the operation and maintenance of the equipment, as well as safety protocols. By considering these factors, you can establish a small-scale laser welding station that is both efficient and safe, enabling you to take advantage of the many benefits of laser welding technology.